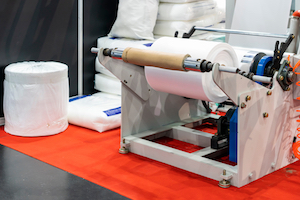

Air Cushion Machines, also known as Air Pillow Machines or Air Packaging Systems, produce air-filled cushions and pillows used in packaging.

On-Demand Air Cushion Production

The Air Cushion Machine is a compact system that produces and inflates air cushions as needed. It is easy to operate and requires minimal training.

The machine operates using rolls or stacks of flat plastic film made from Paper, Polythene, or Polypropylene. As the film is fed into the air pillow machine, it seals and inflates it to form either individual air-filled cushions or a continuous string of interconnected air cushions.

The inflatable air cushions produced are lightweight yet sturdy with excellent cushioning and shock absorption capabilities. They can mould to the shape of the product’s packaging to effectively minimise movement and prevent damage during transit.

Efficient and Versatile Packaging Systems

Our Air Cushion Machines can be manually operated or integrated into automated packaging systems – presenting a versatile and cost-effective solution for a range of packaging operations.

We provide a diverse selection of Air Pillow Packaging Machines with different specifications catering to specific packaging needs. Customisation options and printing options are also available to ensure product quality and operational safety.

- On-Demand Pillows: Provides air cushions on demand for quick and easy packing in semi- or fully automatic modes

- Fast: Tabletop system produces air cushions at speeds over 55 feet per minute

- All Electric: All-electric design does not require compressed air for operation

- Reduce Packaging Costs: Better air retention and improved yield reduces cost per cubic foot

- Dust-Free: The air cushions are dust-free and reduce product loss. They are cleaner compared to EPS peanuts and paper.

- Lower Shipping Costs: Diverse range of cushion sizes fully optimises the space within the shipping boxe

- Adjustable speeds: Easily configurable output to meet different packing needs

- Versatile: Single system produces inflated cushions of varying lengths

- Reliable: Minimal wear items and maintenance required

Mini Air Pillow Machine

- Dimensions (Lx W x H): 405mm x 220mm x 195mm

- Weight: 2.5kg

- Voltage: 110-240v

- Speed: 8 metres per minute

High-Performance Air Pillow Machine

- Weight: 15 kg

- Dimensions (Lx W x H): 460mm x 340mm x 470mm

- Speed: 15 metres per minute

- Voltage: 110-240v

Industrial Air Cushion Machine

- Weight:9kgs

- Power:240w

- Speed: 25m/min(82 feet)

- Voltage:220v/110v, 50HZ-60HZ

- Able to work with overhead hopper, winder or basket

- Speed, air, and temperature adjustable

- No belt, minimal maintenance

- Ideal for large-scale warehouse

- One year warranty

- CE, PSE certified

Mini Air Pillow Machine

- Compact and small

- No spare parts required

- Speed 8 meters per minute

- In-built sensor. It stops automatically when the air cushion film is empty.

- No belt or preheating required

- Works with air cushions and bubble wraps

- Add on options include arm stand and basket or foot pedal

High-Performance Air Pillow Machine

- Speed of up to 15 meters

- External air compressor can be connected

- No belt required

- The machine can produce air pillows, air tubes, air bubbles and bubble mailers

- Adjustable air volume, temperature and length

- Easy operation and minimal maintenance

- CE-certified, quality-guaranteed

Industrial Air Cushion Machine

- Speed up to 25 meters

- No belt needed

- The machine can produce air pillows, air tubes, air bubbles and bubble mailers

- Adjustable air volume, temperature and length

- Easy operation and minimal maintenance

- CE, UL, PSE certified, quality guaranteed

Tài Liệu Sản Phẩm Máy Gối Hơi Bơm Hơi: Download