What is Molecular Sieve?

Understanding Molecular Sieve

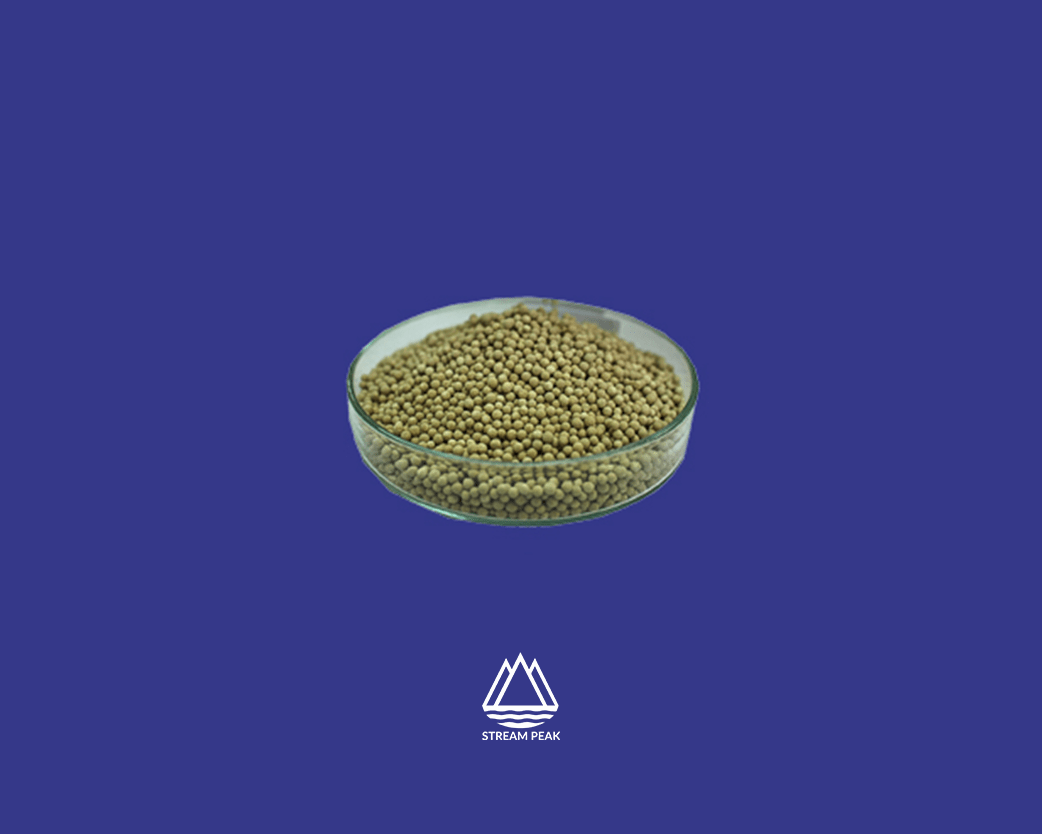

Molecular sieves are highly porous materials used for separating mixtures at the molecular level. They are composed of metal aluminosilicates with a unique crystalline structure that allows them to selectively adsorb gases and liquids based on molecular size and shape. This characteristic makes molecular sieves an invaluable tool in various industrial applications, ranging from gas purification to preserving perishable goods in packaging.

A molecular sieve is a material with pores of uniform size. These pores are small enough to permit only molecules of a specific size to pass through, acting as a “sieve” at the molecular level. The most common types of molecular sieves are made from zeolite, a mineral that naturally has this sieving property and can be synthesised for specific applications. Molecular sieves can adsorb water and other impurities from air and liquids, making them effective desiccants and purifiers.

Composition and Structure

Molecular sieves comprise aluminosilicates, aluminium, silicon, and oxygen minerals, with metal ions like sodium, potassium, or calcium. These components form a three-dimensional crystalline framework that creates a lattice of tiny pores. The size of these pores is precisely controlled during the manufacturing process, resulting in a material that can selectively adsorb molecules based on their size. The unique structure of molecular sieves gives them their sieving capability, allowing them to distinguish between molecules that are only a few angstroms apart in size.

Adsorption Process

The adsorption process of molecular sieves is governed by the size exclusion principle, where only molecules small enough to enter the pores are adsorbed, while larger molecules are excluded. Adsorption occurs when a gas or liquid containing various molecules comes into contact with the molecular sieve material.

Molecules smaller than the pores’ diameter are trapped inside the sieve’s structure, while larger molecules pass over the surface without adsorbing. This selectivity is due to the molecular sieve’s crystalline structure, which acts as a filter at the molecular level.

In addition to size exclusion, molecular sieves can adsorb molecules based on polarity and molecular shape, offering further selectivity in specific applications. The strength of adsorption is influenced by factors such as the pore size of the sieve, the size and shape of the molecules, and the temperature and pressure of the system.

Industrial Applications

Molecular sieves offer superior adsorption capacity and selectivity compared to other desiccants, making them essential in various industrial applications. Their ability to remove water and impurities from gases and liquids at a molecular level makes them critical in producing high-purity chemicals, pharmaceuticals, and petrochemicals.

In the packaging industry, molecular sieves maintain the quality and extend the shelf life of moisture-sensitive products. Additionally, their use in air separation processes, natural gas purification, and refrigerant gas drying highlights their versatility and importance across different sectors. The specific selection of a molecular sieve type depends on the application’s requirements, including the desired purity levels, the nature of the substances to be adsorbed, and the operational conditions.

Types of Molecular Sieves

Molecular sieves are categorised by their pore size, determining the type of molecules they can adsorb. The most common types include:

Molecular sieves are categorised by their pore size, determining the type of molecules they can adsorb. The most common types include:

- 3A Molecular Sieve: With a pore size of 3 angstroms, it effectively adsorbs small molecules such as water, excluding larger molecules like unsaturated hydrocarbons.

- 4A Molecular Sieve: This type has a pore size of 4 angstroms, making it suitable for adsorbing gases and small molecules, including water, CO2, and SO2.

- 5A Molecular Sieve: With a pore size of 5 angstroms, it can adsorb larger molecules, such as hydrocarbons, up to 5 carbon atoms and is commonly used in gas purification.

- 13X Molecular Sieve: Featuring a larger pore size of approximately 10 angstroms, this sieve can adsorb larger molecules, making it ideal for applications requiring the removal of bulk impurities.

Comparison with Other Desiccants

In several ways, molecular sieves differ from other desiccants, such as silica gel and activated alumina. While silica gel and activated alumina are effective for many standard drying applications, molecular sieves offer superior performance where high purity and selectivity are required. Their unique structure and composition enable them to play a critical role in industries where removing specific impurities or controlling moisture is crucial.

- Adsorption Capacity: Molecular sieves generally have a higher adsorption capacity for water and other molecules at low relative humidity, making them more effective in dry conditions.

- Selectivity: The ability to selectively adsorb molecules based on size and shape allows molecular sieves to target specific impurities in a mixture, which is not always possible with other desiccants.

- Regeneration: Molecular sieves can be regenerated (dried out) at higher temperatures than silica gel and activated alumina, allowing for repeated use without significant loss of adsorption capacity.

- Operating Conditions: Molecular sieves perform well under a broader range of temperatures and pressures, making them suitable for more demanding applications.

While silica gel and activated alumina are effective for many standard drying applications, molecular sieves offer higher performance where high purity and selectivity are required. Their unique structure and composition enable them to play a critical role in industries where removing specific impurities or controlling moisture is crucial.

Benefits of Using Molecular Sieves in Packaging

With their unique properties, molecular sieves offer significant advantages, particularly in moisture control, extending the shelf life of packaged goods, and preserving product quality. These benefits are crucial for various industries, including pharmaceuticals, electronics, and food and beverage.

Moisture Control: The primary benefit of using molecular sieves in packaging is their moisture control capabilities. Molecular sieves can adsorb water vapour from the air much more efficiently than other desiccants, such as silica gel or activated clay, especially at low relative humidity levels. This is due to their highly porous structure and the ability to trap moisture within their pores, preventing it from affecting the packaged product. This capability ensures the product remains dry and stable, reducing the risk of spoilage, clumping, or other moisture-related degradation.

Extended Shelf Life for Packaged Goods: By effectively controlling moisture, molecular sieves directly contribute to the extended shelf life of packaged goods. Moisture is often a critical factor in the deterioration of products, leading to issues like mould growth, chemical degradation, or the breakdown of packaging materials. By maintaining a dry environment within the packaging, molecular sieves help prevent these issues, ensuring that products retain their integrity and functionality for longer. This is particularly important for sensitive products, such as pharmaceuticals, where efficacy and safety are directly related to moisture content.

Preservation of Product Quality: Molecular sieves not only extend the shelf life of products but also play a crucial role in preserving their quality. For many products, exposure to moisture can result in altered physical properties, loss of potency, or undesirable chemical reactions. By absorbing and retaining moisture, molecular sieves help maintain the product’s original condition, ensuring consumers receive it as intended. This is especially critical in the case of high-value goods, such as electronics, where even minor exposure to moisture can result in significant damage or loss of functionality.

Considerations for Molecular Sieve Packaging

Implementing molecular sieves into packaging solutions requires careful consideration of several factors to ensure optimal performance and product protection. The effectiveness of molecular sieves in preserving the quality and extending the shelf life of products hinges on selecting the right type of sieve, determining the appropriate quantity, and ensuring compatibility with packaging materials.

Selecting the Right Type of Molecular Sieve

- Assess the nature and requirements of the product being packaged.

- Choose the molecular sieve type (e.g., 3A, 4A, 5A, 13X) based on the size of molecules to be adsorbed and environmental conditions.

- Consider the specific adsorption properties needed for effective moisture control or impurity removal.

Determining the Appropriate Quantity of Molecular Sieve

- Calculate the required quantity based on package volume, expected moisture exposure, and product shelf life.

- Optimize the amount to ensure effective moisture absorption without wasting space or resources.

- Use computational models and empirical testing for precise determination.

Packaging Material Compatibility

- Select materials that are permeable to moisture but impermeable to molecular sieve particles.

- Ensure the packaging material is chemically inert to avoid reactions with the molecular sieve.

- Consider the impact of packaging materials on the adsorption kinetics of the molecular sieve.

- Choose packaging that supports the sieve’s function while protecting the product from external elements.

Conclusion

Molecular sieves play a crucial role in packaging by offering moisture control, extending product shelf life, and preserving quality. Key considerations for their effective use include selecting the correct sieve type, determining the necessary quantity, and ensuring packaging material compatibility. Their ability to address moisture-related challenges efficiently makes them essential in maintaining product integrity.

At Stream Peak Vietnam, we offer quality molecular sieves designed to meet the highest standards of efficiency and reliability. We manufacture molecular sieve bags per ISO 9001 and ISO 14001 certifications, ensuring high performance and adherence to stringent quality management and environmental responsibility principles. Feel free to reach out us and our packaging engineers for more information.

Related Blogs

- Oxygen Absorber vs Silica Gel March 28, 2023

- What is Activated Clay? November 19, 2021

- What are Dunnage Bags? November 19, 2021

- What is Silica Gel? November 19, 2021