Packaging materials are essential in preserving the quality and integrity of products throughout their lifecycle, ensuring they reach end users in optimal condition. Among the wide range of materials, silica gel is a popular packaging solution due to its proficiency in moisture management—a critical factor in maintaining product quality.

Silica gel consists of porous silicon dioxide particles. Its porous nature grants it a significant capacity for moisture absorption, making it a valuable asset in packaging applications. This article aims to provide a comprehensive overview of silica gel, elucidating its composition, properties and role in packaging. By examining its applications and advantages, we seek to underscore the significance of silica gel as a moisture-control agent in diverse industries.

What is Silica Gel?

Silica gel is a highly porous silicon dioxide (SiO2) form commonly used in various industries as a desiccant or moisture absorbent. Despite its name, silica gel is not a gel in the conventional sense but comprises irregularly shaped, hard granules. Its porous structure is characterised by a network of interconnected microscopic pores, providing an extensive surface area for moisture adsorption.

Manufacturing Process

Silica gel is typically manufactured through a chemical process known as sol-gel transformation, which involves the hydrolysis and condensation of silicon alkoxides such as tetraethyl orthosilicate (TEOS) or sodium silicate. This process yields a colloidal suspension, which undergoes gelation and drying to form solid silica gel particles.

Natural silica gel can be obtained from mineral deposits or biosilica sources. For instance, silica gel may be harvested from the silica-rich remains of diatoms, a type of microscopic algae. These natural sources undergo processing to extract and refine silica gel for commercial use.

In synthetic and natural production methods, the resulting silica gel is typically purified and subjected to stringent quality control measures to ensure consistency and efficacy in moisture absorption. Depending on specific application requirements, the granules may be further processed into various forms, such as beads, pellets, or sachets.

Properties of Silica Gel

Desiccating Properties: Silica gel is highly effective at absorbing and adsorbing moisture from its surroundings. This ability stems from its porous structure, which provides a large surface area for the physical adsorption of water molecules. The desiccant can reduce relative humidity to deficient levels, making it an invaluable tool for moisture control in various applications, including packaging, storage, and humidity regulation.

Absorption Capacity: The absorption capacity depends on pore structure, particle size, and ambient conditions. Generally, they can adsorb up to 40% of their weight in water vapour, making them one of the most efficient desiccants. This high absorption capacity allows them to maintain dry conditions within sealed environments, preventing moisture-related damage to sensitive materials such as electronics, pharmaceuticals, and food products.

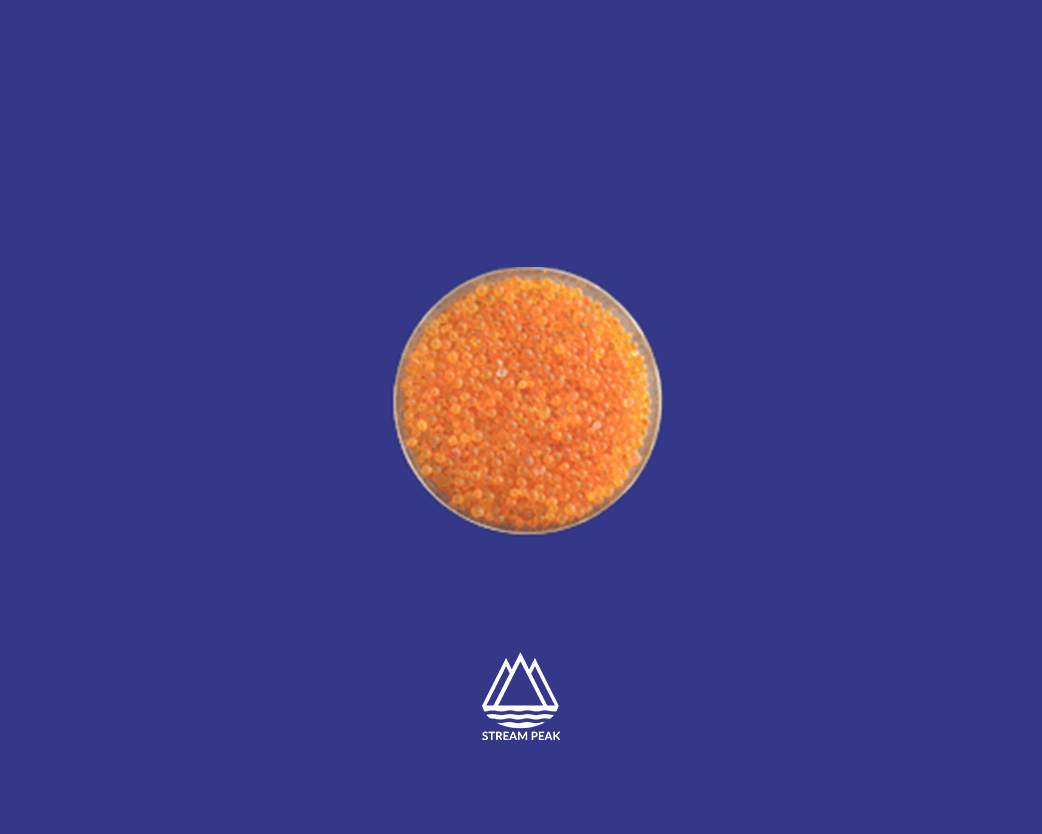

Physical Characteristics: This desiccant typically appears as small, irregularly shaped granules or beads with a hard, glassy texture. Its colour may vary depending on the manufacturing process and any added indicators or impurities, but it is commonly translucent or semi-transparent. The granules are non-reactive, chemically inert, and insoluble in water and most organic solvents, contributing to their stability and suitability for various applications. In addition to its granular form, silica gel may be found in other configurations, such as pellets, powders or silica gel packets.

Uses of Silica Gel

Prevention of Mold, Mildew, and Corrosion: Silica gel plays a crucial role in packaging by effectively controlling moisture levels within enclosed spaces. Excess moisture can lead to the growth of mould, mildew, and corrosion, compromising the integrity and quality of packaged goods.

The desiccant’s ability to absorb moisture vapour helps maintain dry conditions, preventing the proliferation of harmful microorganisms and safeguarding against corrosion, particularly in metal components. This extends the shelf life and usability of packaged products.

Protection of Sensitive Items (Electronics, Pharmaceuticals, Food): Silica gel provide a protective barrier for a wide range of sensitive items, including electronics, pharmaceuticals, and food products. Electronics are vulnerable to moisture damage, which can impair circuitry and functionality. By incorporating desiccants into electronic packaging, manufacturers can mitigate the risk of moisture-related malfunctions and ensure product reliability.

Similarly, pharmaceuticals and food items are susceptible to degradation when exposed to moisture, leading to reduced efficacy and compromised safety. Desiccants help preserve the freshness, potency, and quality of these sensitive goods by maintaining optimal humidity levels and preventing moisture-induced spoilage.

Preservation of Freshness and Quality: In addition to controlling moisture, desiccants aid in preserving freshness and quality in packaged goods. Perishable items such as dried fruits, nuts, and jerky are prone to moisture absorption, resulting in texture changes, flavour loss, and reduced shelf life.

Desiccant sachets or packets can be included in food packaging to absorb excess moisture and maintain product freshness. Furthermore, desiccants’ inert nature ensures that they do not interact with or alter the sensory attributes of packaged foods, preserving their natural taste and aroma.

Types of Silica Gel

Common Forms:

- Sachets: Small, porous packets containing desiccant material, including silica gel. They are commonly used in various packaging applications to control moisture levels within confined spaces. Silica gel sachets are available in different sizes and configurations to accommodate specific packaging needs, from individual product packages to shipping containers.

- Canisters: Desiccant canisters are rigid containers filled with desiccant material, such as silica gel beads or pellets. These canisters are designed for larger packaging systems or storage environments where consistent moisture control is essential. Canisters offer a convenient and efficient means of maintaining dry conditions within sealed containers, protecting packaged goods from moisture-related damage.

- Beads: Silica gel beads are spherical granules with high surface area and moisture-absorbing capacity. These beads are commonly used as loose-fill desiccants in various packaging applications. They can be dispersed within product packaging or incorporated into specialised desiccant sachets to absorb moisture effectively. Silica gel beads are available in different sizes and formulations to suit specific moisture control requirements.

Specialised Applications:

- Humidity Indicator Cards: Humidity indicator cards are paper-based or polymer-based cards containing moisture-sensitive chemicals, which undergo colour changes in response to variations in humidity levels. Silica gel is often used together with humidity indicator cards to provide accurate moisture monitoring within sealed packages. These cards offer visual indicators of relative humidity levels, helping users assess the effectiveness of moisture control measures and identify potential damage.

- Dehumidifier Boxes: Dehumidifier boxes are compact containers with desiccant material, such as silica gel, designed to remove excess moisture from enclosed spaces. These boxes are commonly used in storage areas, closets, cabinets, and small rooms to prevent mould, mildew, and moisture-related damage. Dehumidifier boxes provide a convenient and portable solution for maintaining dry conditions in various environments.

- Moisture Barrier Bags: Reactive barrier packaging incorporates desiccant materials, including silica gel, into specialised barrier films or coatings applied to packaging materials. These moisture barrier bags actively prevent moisture vapour and other volatile compounds, providing enhanced protection against moisture-related damage and preserving the quality of packaged goods. Moisture barrier bags are handy for sensitive electronic components, pharmaceuticals, and food products.