What are Dunnage Bags?

Dunnage bags, also known as airbags, air cushions, or inflatable bags, serve as a critical component in the transportation and storage industries, ensuring the safety and stability of goods during transit. These bags are designed to fill voids, brace loads, and absorb vibrations within containers, trailers, or ships, preventing cargo from shifting and becoming damaged.

Understanding Dunnage Bags

A dunnage bag is a flexible, inflatable bag made from various materials, including polyethene, polypropylene, and even paper, with an inner layer that holds air. They come in different sizes and strengths to accommodate the weight and sensitivity of the cargo, as well as the size of the voids that need to be filled. The principle behind their use is simple yet effective. When inflated, they create a cushioning and stabilising force between loads, adapting to the space and contours of the cargo to minimise movement and friction.

The type of goods being transported allows the application of dunnage bags. Whether pallets of boxed products, barrels, equipment, or any other cargo, dunnage bags can be strategically placed and inflated to secure the load. This adaptability extends to various modes of transportation, including sea, road, rail, and air freight, demonstrating their universal utility in the logistics sector.

Dunnage bags protect goods during transportation and storage. By preventing cargo from shifting, they significantly reduce the risk of damage, ensuring products arrive at their destination in the same condition as when loaded. This minimises financial losses due to damaged goods and enhances safety by preventing accidents from unbalanced loads.

Furthermore, dunnage bags play a vital role in optimising container space. By filling voids and stabilising cargo, they allow for more efficient packing, leading to cost savings in shipping and a reduction in the carbon footprint associated with transportation. The ease of use and quick inflation and deflation processes make dunnage bags a time-efficient solution for fast-paced logistics environments, where saving time translates directly into operational efficiencies.

Types of Dunnage Bags

Selecting the right dunnage bags for cargo needs and understanding their sizing are critical steps in ensuring the safety and integrity of goods during transportation. Proper selection and sizing not only protect the cargo but also optimize the use of space and resources.

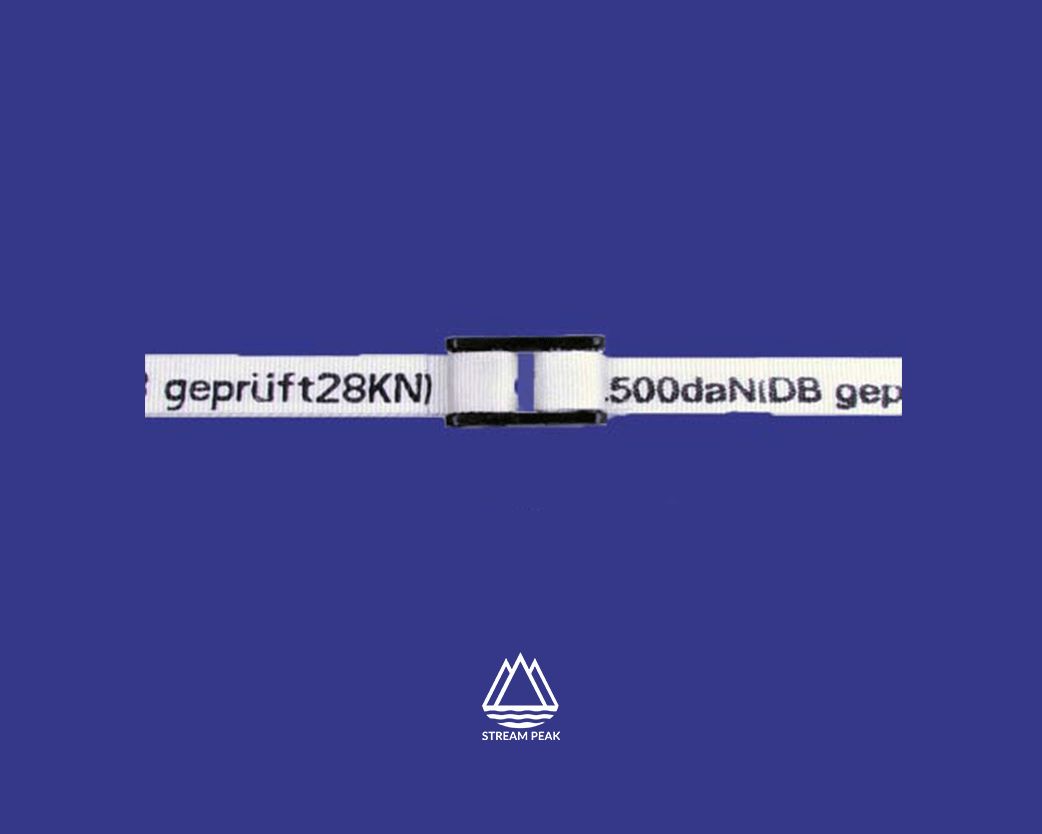

Polywoven Dunnage Bags: These are made from woven polypropylene, offering high strength and durability. They resist punctures and moisture, making them ideal for heavy-duty applications and harsh environments. Polywoven dunnage bags can be reused multiple times and are suitable for rail, sea, and road transportation.

Paper Dunnage Bags: These dunnage bags are an eco-friendly option constructed from one or more layers of kraft paper. They are commonly used for lighter applications and are recyclable, but they might not be as durable as poly woven bags, especially in moist conditions.

Vinyl Dunnage Bags: Vinyl bags are known for their excellent air retention and water resistance, making them suitable for protecting sensitive cargo. They are particularly useful in air freight due to their lightweight nature and superior cushioning capabilities.

| Material Type | Pros | Cons |

|---|---|---|

| Polywoven | High strength and durability, Moisture and puncture resistance, Reusable | More expensive than paper and not as environmentally friendly as paper |

| Paper | Cost-effective, Recyclable and eco-friendly, Lightweight | Less durable than poly woven, especially in moist conditions, Limited reuse |

| Vinyl | Excellent air retention, Water-resistant, Good for sensitive cargo | More expensive than paper and some polywoven options, Less environmentally friendly due to difficulty in recycling |

Inflation Tools in Dunnage Bag Application

The efficiency and effectiveness of dunnage bags greatly depend on proper inflation. Using the right inflation tool is crucial for achieving the correct pressure and fill.

- Manual Pumps: Suitable for smaller operations or where few dunnage bags are used. They are portable and do not require power sources.

- Electric or Battery-Operated Inflators: Ideal for larger operations with frequent dunnage bag use. These tools offer faster inflation and consistent pressure, enhancing operational efficiency.

- Pressure Regulators: Ensuring that dunnage bags are not over- or under-inflated is key to their performance. Pressure regulators help maintain the optimal pressure, maximising the stability and protection provided by the bags.

Uses and Applications

Securing Loads in Containers and Trailers: Dunnage bags are extensively used in shipping containers and trailers to fill voids between cargo loads, preventing movement and friction that could lead to damage.

Stabilisation in Rail Transportation: In rail freight, dunnage bags provide vital stabilisation for goods susceptible to shifting due to the dynamic forces experienced on railroads.

Protection in Sea Freight: Used within shipping containers, dunnage bags absorb vibrations and impacts from waves and handling, safeguarding goods during long sea voyages.

Load Bracing in Air Freight: Due to their lightweight nature, especially vinyl dunnage bags, they are ideal for air freight, offering protection without significantly adding to the cargo weight.

Considerations When Choosing Dunnage Bags

First, you should start by deciding the size of the voids between cargo items or cargo and the container walls. Start by determining this measurement, which will guide the size of the dunnage bag needed. Next, ensure the bag’s dimensions are appropriate for the void space, with some bags being specifically designed for narrow or wide gaps.

Select a dunnage bag with the appropriate strength (level 1 to 5) based on the weight of the cargo and the forces it may encounter during transport. The working pressure of the bag should also match the requirements for effectively securing the load without overinflation. Larger containers and heavier cargo loads may require larger and stronger dunnage bags. Ensure the selected bag adequately fills the space and provides sufficient bracing force.

- Type of Cargo: Consider the cargo’s weight, sensitivity, and nature. Heavy or sharp-edged goods may require more durable dunnage bags, such as polywoven materials, whereas lighter, more delicate items might be well-served by paper or vinyl bags.

- Mode of Transportation: Different transportation modes (sea, air, rail, or road) subject cargo to varying degrees of movement and environmental conditions. Select dunnage bags that are suited to withstand specific challenges, such as moisture resistance for sea freight or lightweight bags for air freight.

- Load Configuration: The way cargo is arranged in the container or vehicle influences the type and size of dunnage bags needed. Consider the distribution of weight and the presence of void spaces when selecting bags.

Installation and Inflation

Always wear gloves and safety glasses when installing and inflating dunnage bags to protect against potential injury. Overinflating dunnage bags can lead to rupture and possible injury. Always adhere to the recommended pressure limits. Inspect dunnage bags for any signs of wear, tear, or damage before use. Damaged bags should not be used as they may fail to secure the cargo properly. Ensure personnel involved in packing and loading are trained in properly using dunnage bags, including installation, inflation, and safety protocols.

Inflating:

- Use a pressure regulator to avoid overinflation, which can damage the dunnage bag and cargo.

- Inflate the bag slowly to monitor pressure and adjust as needed.

- Follow the manufacturer’s recommended pressure guidelines to ensure optimal performance.

Deflating:

- Carefully open the valve and allow the air to escape slowly. Avoid puncturing the bag during deflation.

- Once deflated, gently remove the bag from the void space to prevent damage to the bag or cargo.

- Store deflated dunnage bags in a dry, clean place for reuse.

Guide to Installing Dunnage Bags

- Assess the Cargo Layout: Before installing dunnage bags, evaluate the cargo arrangement and identify void spaces that need to be filled to prevent movement.

- Choose the Appropriate Dunnage Bag Size: Select a dunnage bag that fits the void space without overstretching. The bag should be slightly larger than the gap to ensure a snug fit once inflated.

- Position the Dunnage Bag: Place the dunnage bag in the void space between the cargo loads or between the cargo and the container wall. Ensure it’s positioned flat and that the inflation valve is accessible.

- Attach the Inflation Tool: Connect the inflation tool (manual pump, electric inflator, etc.) to the dunnage bag’s valve. Ensure a secure connection to prevent air leakage during inflation.

- Inflate the Dunnage Bag: Begin inflating the dunnage bag, monitoring the pressure closely. Inflate until the bag is firm and snugly fills the void space, providing adequate pressure to stabilise the cargo without overinflation.

- Disconnect the Inflation Tool: Once the bag is inflated correctly, carefully disconnect the inflation tool. Ensure the valve is securely closed to prevent air loss.

- Final Inspection: Check the dunnage bag’s placement and firmness to ensure it adequately supports and stabilises the cargo. Adjust if necessary.

Conclusion

Dunnage bags are a packaging solution for secure transportation, offering a cost-effective and efficient solution to one of the logistics industry’s most pressing challenges: ensuring cargo arrives at its destination safely. By adhering to best practices and safety guidelines, shippers can leverage dunnage bags to optimize load stability, enhance container utilization, and contribute to more sustainable transportation practices.

At Stream Peak Vietnam, we offer dunnage bags manufactured with German technology, ensuring the highest standards of quality and durability. Our team of packaging engineers supports through comprehensive training sessions covering installation, inflation, and essential safety protocols. This ensures that all users are well-equipped to maximize the benefits of our dunnage bags, enhancing cargo security and efficiency. Should you require further information or assistance, feel free to contact us.